How CAD and BIM Services Streamline Commercial Construction

How CAD and BIM Services Streamline Commercial Construction

Delivering Efficiency and Cost Savings

The integration of Computer-Aided Design (CAD) and Building Information Modeling (BIM) technologies has transformed the landscape of construction planning and execution. These technologies streamline construction projects and significantly reduce costs by addressing traditional challenges such as trade conflicts and spatial clashes.

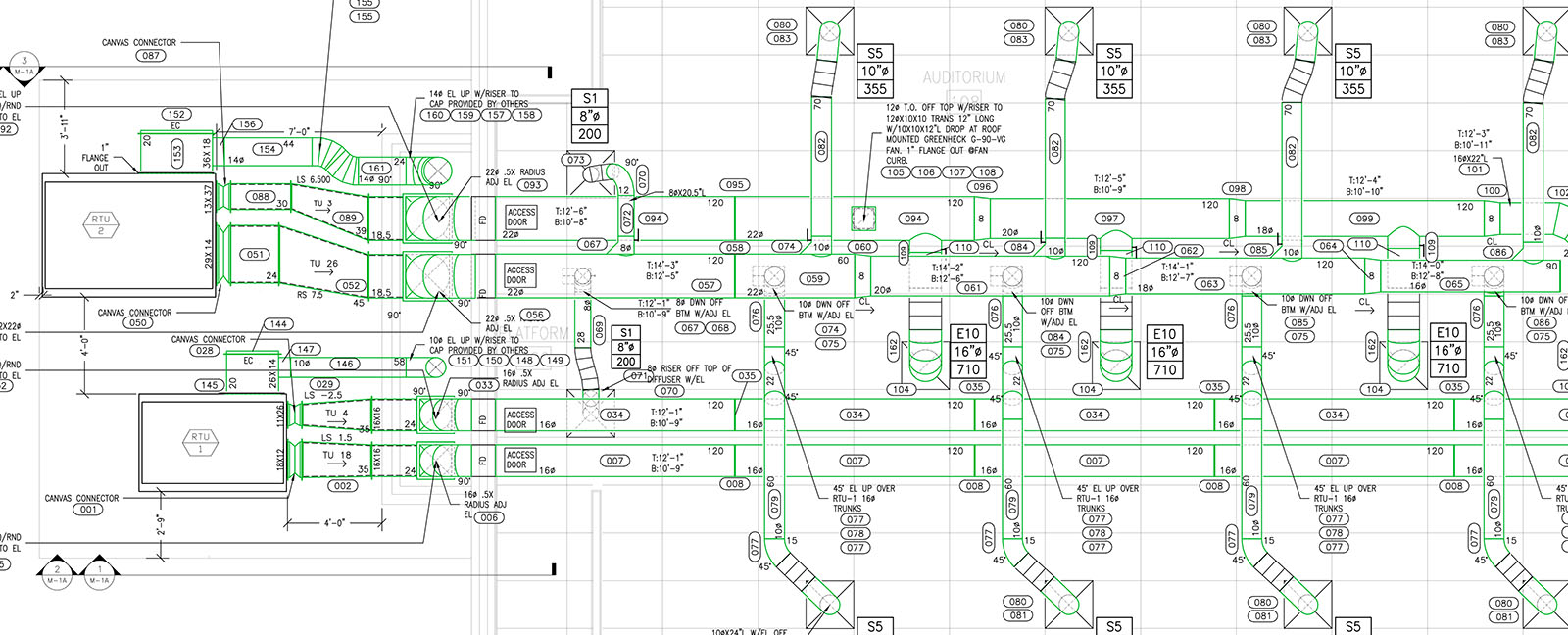

Understanding CAD and BIM in HVAC Duct Design

In recent years, CAD and BIM technologies have advanced the efficiency of HVAC duct designs across a diverse range of building architectures. These technologies enable designers and engineers to create more accurate and tailored HVAC systems that are specific to the unique demands of each building’s architecture. With CAD, the precision in drafting and modeling of ductwork is significantly improved, allowing for the meticulous representation of the HVAC systems in the building’s layout. This precision is crucial in complex structures where space is limited, and the integration of systems is intricate.

BIM, on the other hand, elevates this efficiency to a new level. It allows for the integration of HVAC designs into the overall building model, fostering a holistic approach to building design and construction. BIM’s capabilities in clash detection are particularly beneficial for HVAC systems. It ensures that ductwork does not interfere with other building elements, like electrical wiring or plumbing, and adheres to spatial constraints.

This preemptive detection and resolution of potential conflicts avoid costly rework and delays during construction.

Moreover, BIM’s ability to model energy efficiency and airflow dynamics aids in creating HVAC systems that are not only physically compatible with the building architecture but also optimized for energy use and environmental sustainability.

In essence, the integration of CAD and BIM technologies in HVAC duct design represents a significant leap forward in building design. By allowing for more precise, efficient, and sustainable HVAC systems, these technologies ensure that modern buildings meet both the functional and environmental standards required in today’s construction industry.

Clash Detection in BIM

The process of BIM clash detection plays a pivotal role in preempting construction issues. It involves identifying hard clashes (where two systems or components physically intersect), soft clashes (where elements lack the necessary space or buffer to operate safely), and workflow clashes (involving scheduling conflicts or project management misalignments). New technologies in BIM have enhanced the ability to detect these clashes early, promoting more efficient planning, and minimizing any waste of resources.

Budget and Time Savings

BIM-based tools significantly reduce construction rework caused by design and engineering errors. They facilitate higher accuracy in construction drawings and installation, lower numbers of iterations during onsite installation, and improved interdisciplinary coordination and collaboration. This leads to lower material costs, reduced onsite risks, and overall higher project efficiency. The early detection and resolution of clashes means that issues can be resolved before the actual construction begins, thereby saving time and money.

Impact on End Results

The use of CAD and BIM in construction projects, and especially with regard to HVAC duct design, leads to better end results across a range of safety, sustainability, and functionality concerns. These technologies offer a comprehensive view of the project, allowing for improved decision-making and enhanced collaboration among different stakeholders. By resolving potential design conflicts early, they ensure the safety and functionality of the building systems, contributing to cost savings, on-time scheduling, and the sustainability of the project as a whole.

Finding the Right Partner

Did you know your company can take advantage of the cutting-edge BIM and CAD teams at The Cincinnatus Group? Outsourcing HVAC CAD and BIM services offer numerous benefits, including cost-effectiveness, access to specialized expertise, faster turnaround times, higher quality and precision, and scalability. As the HVAC industry continues to evolve, embracing outsourcing can be a strategic move for contractors looking to stay competitive and efficient.

You can even offer our services as your own. The Cincinnatus Group’s white-label CAD & BIM services give your business an unprecedented edge in the marketplace. By integrating these advanced design and construction methodologies, your company can promise superior quality, efficiency, and collaboration to your clients. It’s not just about constructing buildings; it’s about building brands that resonate with innovation and excellence. Embrace CAD & BIM, and let your brand be synonymous with the future of construction.

Visit us at www.TCGDUCT.com. We’re a systematic ductwork materials management company, and we’re “called to solve, where others struggle.”

Additional Services from The Cincinnatus Group

At The Cincinnatus Group, we also offer the highest quality contracted services in the areas of contracted sales/marketing, estimating and take-offs, and CAD/BIM/Coordination Drawings.

For any HVAC Fabricator looking to step up their game and ensure they’re working with the best, The Cincinnatus Group is ready to help. Contact us today at 878-295-8009 or through our website’s Contact Us page, and let’s build something great together.