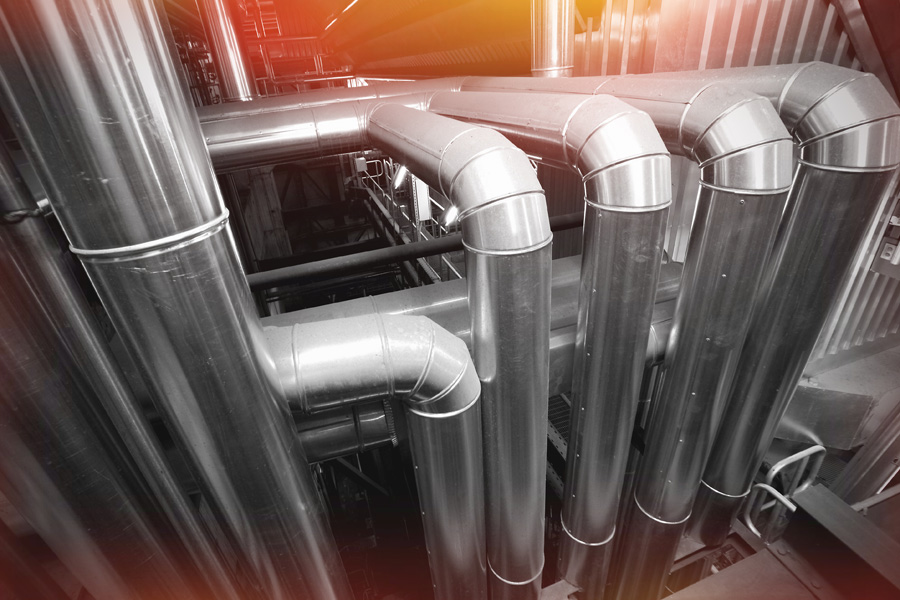

New Year, New Capacity: Industrial Ductwork Sourcing in 2026

From Our Reliable Sourcing Network to Our Strategic Partners, TCG is the Right Choice

by Heather Rodehaver, Business Development at TCG

If you source industrial ductwork for commercial or industrial projects, you already know the ground has shifted. Steel and aluminum tariffs have doubled. Specialty metals are harder to get.

Fabricators are running at reduced capacity because they can’t find enough skilled workers. And if you’re relying on a single supplier to deliver everything you need, on time and on budget, you’re carrying more risk than you may realize.

More than likely, none of this is news to you. What is worth taking a look at is how these forces converge, at what separates contractors who navigate volatility from those who get buried by it.

At The Cincinnatus Group, we’ve spent 21 years building a sourcing network specifically for this kind of environment.

Today we’re examining the current sourcing landscape for industrial ductwork, the risks contractors face without strategic partners, and how TCG’s expanding network provides the kind of stability that keeps projects moving forward.

The Sourcing Landscape Has Changed

In June 2025, the U.S. government increased Section 232 tariffs on most imported steel and aluminum from 25% to 50%, effective June 4. In August 2025, the Department of Commerce added 407 additional Harmonized Tariff Schedule (HTSUS) codes for steel- and aluminum-derivative products to the Section 232 list, extending tariffs to those products based on their steel or aluminum content. For contractors and fabricators in the HVAC and sheet metal industries, the impact was swift.

Coil-based steel products surged as much as 50% in the first half of 2025. Midwest aluminum premiums spiked 54% after the tariff announcement. Fabricators across the country began signaling 10% to 12% price increases, with additional hikes expected as the full weight of the tariff expansion registered across the supply chain.

Stan Kolbe, executive director of government and political affairs at SMACNA, put it bluntly: the second round of tariff increases are “even more painful to contractor bottom lines.” Even firms that prioritize domestic sourcing are being squeezed when U.S. mills can’t meet demand.

That’s the steel and aluminum story. Now layer on what’s happening with specialty metals. Contractors sourcing stainless steel, PCD coated duct, or galvanneal face tighter availability and longer lead times. When import channels constrict, domestic production can’t always fill the gap, creating supply shortfalls even for shops committed to buying American.

Then there’s the labor side of the equation. The HVAC industry faces a significant technician shortage, with estimates of over 100,000 unfilled positions nationwide in 2025, compounded by an aging workforce where many tradespeople are approaching retirement. At the fabrication shop level, this means reduced production capacity, extended lead times for custom and welded ductwork, and less flexibility when schedules need to move.

Today’s talent shortage is compounding every other pressure in the supply chain.

On top of all this, the steel supply chain itself is consolidating. The announced merger between service center giants Ryerson and Olympic Steel (October 2025, expected close Q1 2026) is reshaping how fabricators access material. Smaller buyers are wondering whether their orders will still receive the attention and flexibility they’ve relied on. When your service center partner changes, your pricing power, lead time commitments, and access to specialty products can change with it.

The Real Risks of Going It Alone

Every contractor manages supply chain risk. The question is whether you’re managing it proactively or just hoping things work out.

- Single-supplier dependency is the most common vulnerability we see. When your one fabricator gets backed up, can’t source a specialty metal, or raises prices mid-project, you have no leverage and no alternatives. You’re at the mercy of their capacity and their supply chain. In a 50% tariff environment, that’s a position no contractor wants to be in.

- Price volatility hits hardest on projects with long timelines. You bid a job based on today’s material costs, but by the time you’re placing orders, prices have moved. The question is: without a sourcing partner, can you identify the best pricing across multiple suppliers in real time? If not, you’re exposed to margin erosion that’s difficult to recover from.

- Schedule risk from material delays compounds quickly. Quality materials lose their appeal if they can’t be delivered on schedule. A single late delivery can idle field crews and create delays that ripple through the entire project timeline.

- Quality inconsistency follows naturally. Under deadline pressure, contractors scramble for alternative suppliers they haven’t vetted. The ductwork arrives, and it doesn’t meet spec. Now you’re dealing with rework, field modifications, and problems that could damage your reputation.

The Network Advantage: 21 Years of Cultivated Relationships

There’s a reason TCG’s sourcing network is effective in this market. It wasn’t built to handle easy conditions. It was built over 21 years of navigating exactly the kind of volatility contractors face right now.

When we say “network,” we don’t mean a vendor list. We mean multiple qualified fabricators for each product category. Our partners are vetted, tested, and maintained through ongoing business relationships. If one shop is at capacity or a material is unavailable through one channel, alternatives are already in place. This is the kind of redundancy that takes years to build, and it’s the single biggest advantage a sourcing partner can offer in today’s market.

Because TCG works with these fabricators daily across thousands of annual projects, we have real-time visibility into capacity and lead times. We know who has open production slots, who’s backed up through the quarter, and where the best lead times are for specific materials and gauges.

Few suppliers or contractors have access to intelligence like this. It can only come from the kind of volume a specialized sourcing company like TCG maintains.

Our network emphasizes domestic fabrication partnerships, which reduces exposure to import tariffs and the unpredictability of international supply chains. When tariffs shift—and they will continue to shift—having domestic options already in place is essential.

Volume matters too. When you’re one contractor placing one order, you’re in a queue. When your order is part of a larger, ongoing relationship between TCG and a fabricator, it gets handled differently.

TCG as Risk Mitigation: More Than a Vendor

A sourcing network is only as valuable as your ability to access it. That’s where TCG’s bolt-on services complete the picture.

TCG operates under your brand as a seamless extension of your team. Our bolt-on model means no long-term commitments, no capital investment, and no disruption to your existing client relationships. You get specialized sourcing capacity when and where you need it, scaled to the demands of each project.

Single-source responsibility is at the core of what we provide. One order, one point of accountability for every ductwork component. We handle both industrial duct like welded, stainless steel, and galvanneal AND standard rectangular, spiral, double wall, and more.

Instead of managing multiple fabricator relationships, coordinating deliveries from different shops, and chasing order statuses across several vendors, you make one call. We handle the rest.

Take Advantage of TCG’s Expanding Network

A strong network doesn’t stand still. It grows to meet the needs of the contractors it serves. In keeping with that philosophy, TCG moves forward by continuing to add strategic partnerships that expand our ability to serve as a true single-source solution.

Dust Collection Systems: Nordfab Partnership

TCG is now an authorized Nordfab Dealer. Nordfab is a leading manufacturer of Quick-Fit® clamp-together ductwork for dust, mist, and fume collection, headquartered in Thomasville, North Carolina, with over 45 years in the clean air industry.

Dust collection is a critical component of industrial HVAC applications. Woodworking, metalworking, food processing, and manufacturing environments all require effective particulate management for worker safety and regulatory compliance. Nordfab’s Quick-Fit system installs in half the time of traditional ducting (no rivets, screws, or welding required) and is available in galvanized and stainless steel to match your application requirements.

For contractors, this partnership means you can now source dust collection systems through the same trusted partner handling your industrial ductwork. One relationship, one coordination point, fewer vendor headaches.

Rooftop Support Systems: MIRO Products

TCG is also a MIRO Distributor. MIRO Industries has been providing rooftop support solutions since 1982 and is recognized as both the longest-standing and longest-lasting solution provider in the category, backing their products with a 20-year warranty.

Rooftop HVAC equipment requires proper support systems to protect roof membranes, ensure equipment longevity, and maintain compliance with wind and seismic codes. Improper support leads to costly roof damage, equipment failures, and warranty issues—problems that are entirely avoidable with the right products and the right partner.

MIRO’s product range includes mechanical unit supports, duct supports, pipe supports, service access platforms, stair assemblies, and wind/seismic compliant solutions—all made in the USA from hot-dip galvanized steel or stainless steel. For a deeper look at why rooftop supports matter, read our earlier article: The Importance of Rooftop Supports in HVAC.

The Time to Evaluate Is Now

Market volatility, increased tariffs, supply chain breakdowns, and labor shortages: that’s just what’s happening today. You need an industrial ductwork sourcing partner than can handle tomorrow too.

For 21 years, The Cincinnatus Group has been the strategic sourcing partner that contractors and fabricators trust when the stakes are high. Our network, our systems, and our expanding product partnerships exist for one reason: to give you options, stability, and precision in a market that offers less of all three every year.

At The Cincinnatus Group, we’re “Called to Solve, Where Others Struggle.”

Ready to discuss your 2026 sourcing strategy? Contact The Cincinnatus Group today at 878-295-8009 or visit www.tcgduct.com/contact to start the conversation.

Let’s start planning your next success.

To learn more about any of the services provided by The Cincinnatus Group, including Contracted Estimating and Take Offs, CAD/BIM/Coordination Drawings, and Project Management Assistance, please call us at 878-295-8009, or visit our Contact Us page today.