New Year, New Capacity: Strategic Estimating Planning for 2026

Why Smart Contractors Treat Takeoff Capacity as a Strategic Asset

by Heather Rodehaver, Business Development at TCG

January brings fresh budgets, new project pipelines, and the annual challenge every HVAC contractor and fabricator faces: do we have the estimating capacity to capture the opportunities ahead?

Honestly, most contractors just keep their heads down and slog forward. They deal with problems reactively. After all, why plan ahead when you can try to put the fires out as they happen? OK, that was a bit harsh, but you know it’s often true. PM’s wait until deadlines pile up, then scramble to hire or work overtime. By then, opportunities have already slipped away.

The contractors who win consistently in competitive markets take a different approach. They treat estimating capacity as a strategic asset, not an administrative function.

“The question isn’t whether you can handle your current workload,” says Drew McCaffrey, founder of The Cincinnatus Group. “The question is whether you can capture opportunities you’re currently missing. That’s where growth lives.”

As the first quarter of 2026 unfolds, project owners finalize annual budgets. Developers release RFPs. Commercial clients compare contractors for spring and summer starts. Your capacity to respond quickly and accurately during these critical months shapes your entire year. Here’s how to think strategically about estimating capacity for 2026.

The Capacity Question Nobody Asks

Start with honest math. How many bids can your estimating team realistically handle per week? Not theoretically. Actually. Count last month’s output. Now ask: what’s your win rate on those bids?

Most contractors operate around a 10% to 15% win rate. That means for every ten bids submitted, one becomes a project. Simple arithmetic reveals the growth equation: more bids equals more wins.

If your team handles ten bids weekly at a 10% win rate, you’re winning four projects monthly. Double your bidding capacity to twenty per week, and you’re winning eight projects monthly. Same win rate. Double the revenue. Same estimating headcount.

The math sounds obvious. So why don’t more contractors pursue it?

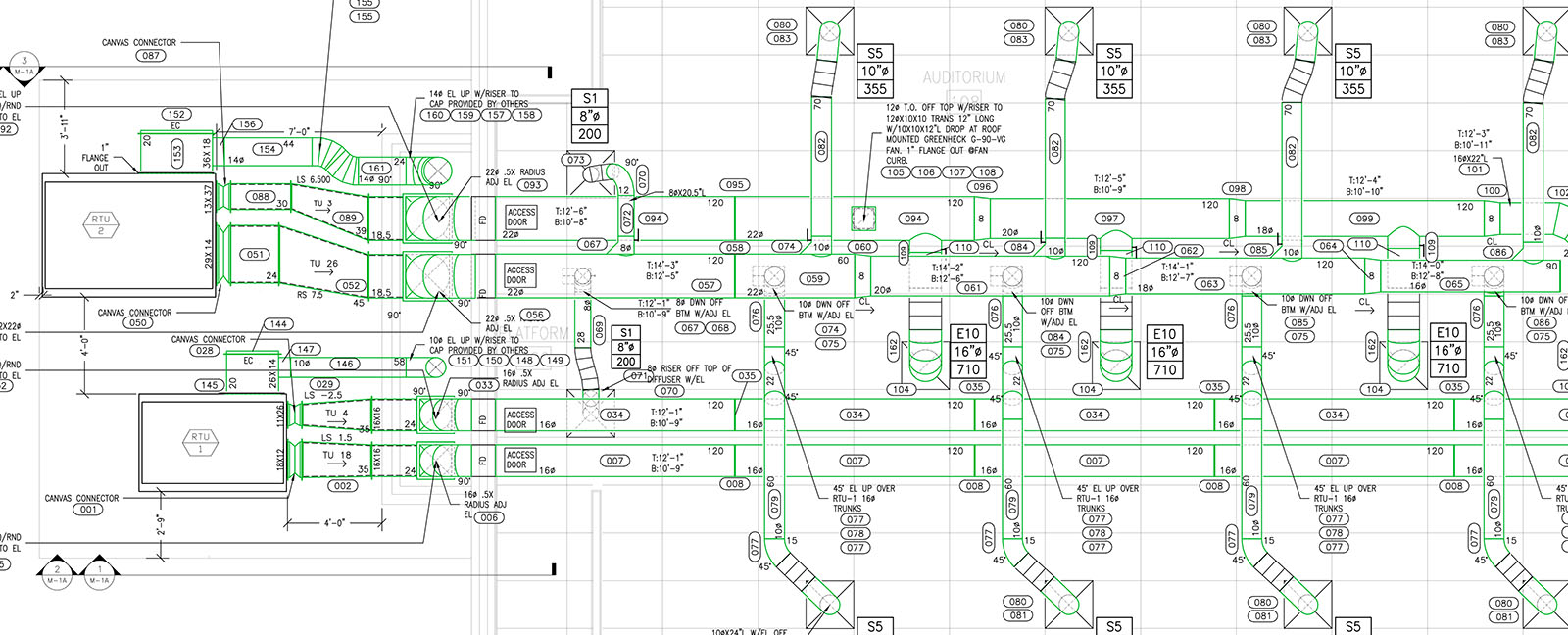

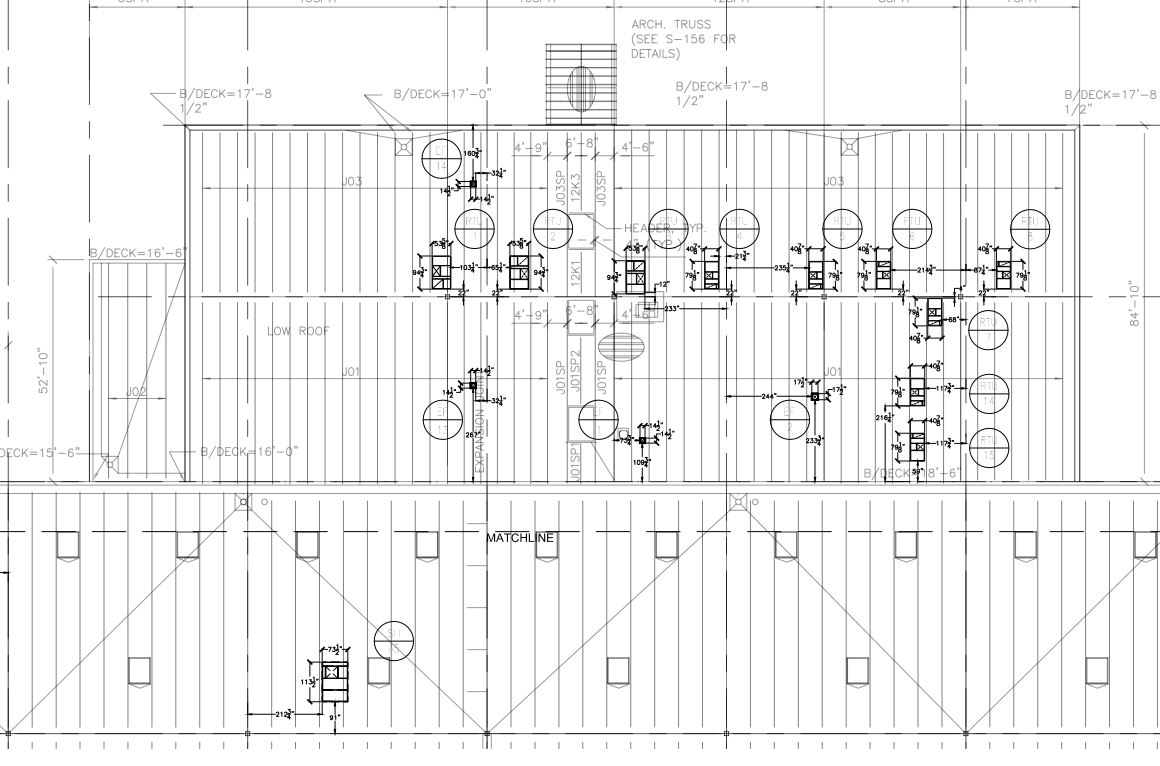

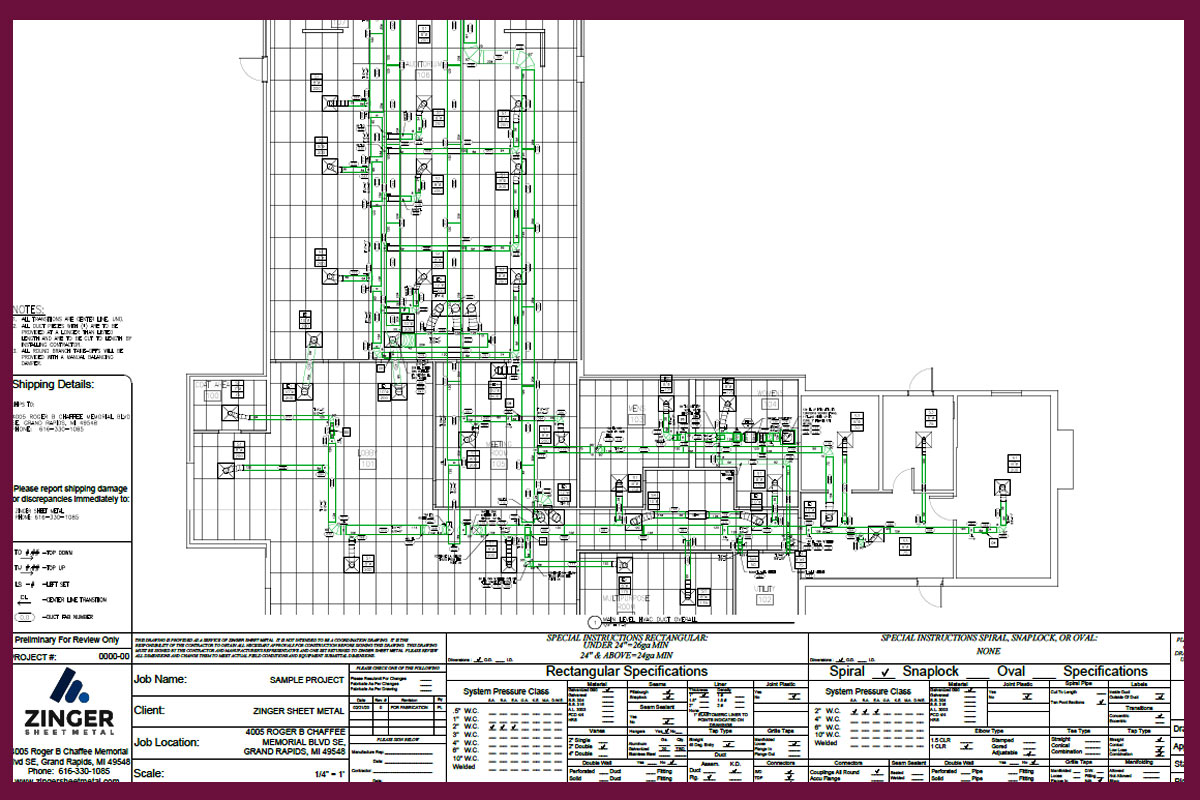

Because 70% of your estimators’ time disappears into takeoffs. Measuring ductwork. Counting fittings. Calculating quantities. This detailed work must happen before pricing, before strategy, before client conversations. Takeoffs create the foundation. They also create the bottleneck.

Warning Signs Your Capacity Is Holding You Back

Capacity constraints rarely announce themselves. They creep in gradually until they become normal. Watch for these warning signs:

Missed bid deadlines. When “we just couldn’t get to it in time” becomes a regular phrase, you’re not managing workload. You’re rationing opportunity.

Rushed estimates with errors. Speed without accuracy costs more than missed deadlines. One material shortage or significant overbid damages relationships for years.

Team burnout. Your best estimators working sixty-hour weeks during busy seasons isn’t dedication. It’s a system failure waiting to cause turnover.

Turning away opportunities. Every “we’re too busy to bid that” hands revenue directly to competitors. You’ll never see those dollars on a financial statement, but they’re real losses.

Over-reliance on key personnel. If one person’s vacation or illness creates crisis, you don’t have a team. You have a single point of failure.

These symptoms share a common cause: treating estimating capacity as fixed rather than flexible. The contractors who thrive treat capacity as something they can strategically expand when opportunities warrant.

The Build vs. Bolt-On Decision Framework

When capacity constraints emerge, contractors face a choice. Build internal capability or leverage external services. The right answer depends on several factors.

Fixed Costs vs. Variable Costs

Hiring an experienced estimator means committing to salary, benefits, software licenses, and training before a single takeoff gets completed. That investment runs whether you’re busy or slow. Industry data suggests fully-loaded estimator costs can reach $130,000 to $150,000 annually when you factor everything in.

Bolt-on services convert that fixed expense into variable cost. You pay for takeoffs when you need them. During slow periods, costs drop. During surges, capacity expands. Your expense moves with revenue rather than against it.

Time to Productivity

Finding qualified estimators takes months in today’s talent market. Training them to your standards takes additional months. From decision to productivity, you’re looking at six months minimum—often longer.

Bolt-on services deliver capacity immediately. The Cincinnatus Group maintains teams ready to start on your projects today, not next quarter.

Risk Factors

Internal hires carry turnover risk. When that estimator you spent months recruiting and training leaves for a competitor, you’re back to square one. Industry turnover rates for skilled estimators run as high as 30% annually.

Established bolt-on partners spread that risk across their organization. Their training systems, quality controls, and team depth mean your capacity doesn’t depend on any single person.

Scalability Needs

Can you predict your 2026 workload precisely? Most contractors can’t. Markets shift. Opportunities appear unexpectedly. Major projects land with tight timelines.

Internal capacity scales slowly. Bolt-on services scale instantly. Whether you need five takeoffs or fifty this month, external partners flex to match demand.

The Hybrid Approach: Best of Both Worlds

The build vs. bolt-on question presents a false choice. Many successful contractors run hybrid models that capture advantages from both approaches.

Core capability stays in-house. Your internal team handles routine projects, maintains institutional knowledge, and builds client relationships. They understand your systems, your standards, and your competitive positioning.

Surge capacity comes from partners. When bid volume spikes, when complex industrial projects arrive, or when your team needs bandwidth for strategic work, bolt-on services absorb the overflow. Your clients see consistent quality under your brand. You capture opportunities that would otherwise go to competitors.

This hybrid model turns estimating capacity from a constraint into a competitive weapon. You’re never turning away work because you’re “too busy.” You’re never paying for idle capacity during slow periods. You’re strategically deploying resources where they generate the highest return.

Seasonal Timing Matters

Q1 is when 2026 backlogs get built. The projects bid in January, February, and March fill schedules for the entire year. Contractors who enter Q1 with constrained capacity watch opportunities flow to better-prepared competitors.

Consider your seasonal patterns. When does bid volume typically spike? Do you have capacity when it matters most, or are you always playing catch-up during your busiest periods?

Strategic capacity planning means having resources in place before the surge hits. Establishing relationships with bolt-on partners now means immediate access when Q1 demand arrives. Waiting until you’re overwhelmed means scrambling while competitors capture the work you should be winning.

The Track Record That Matters

Bolt-on services only create value if they deliver accuracy. Errors in takeoffs cascade into material shortages, cost overruns, and damaged client relationships.

The Cincinnatus Group completed over 2,200 takeoffs in 2024. Through systematic quality control processes built on EOS principles, we achieved zero corrective action reports throughout all of 2025. That precision comes from 21 years of focused expertise in HVAC ductwork and our unique “Beehive Training Program”—the industry’s only comprehensive training ground and curriculum for developing specialized estimating talent.

When you partner with TCG, your clients see professional, accurate takeoffs delivered under your brand. You maintain relationships while our teams handle the detailed grunt work. Your estimators spend less time counting fittings and more time on pricing strategy, client development, and winning work.

Planning Your 2026 Capacity Strategy

Strategic capacity planning starts with three questions:

- What’s your current realistic weekly bid capacity?

- What would capturing 50% more opportunities mean for your 2026 revenue?

- Do you have the estimating bandwidth to pursue that growth?

If the answers reveal a gap between opportunity and capacity, you have options. Build internal capability over the coming months. Establish bolt-on partnerships for immediate flexibility. Or create a hybrid model that leverages both approaches strategically.

The contractors who win in 2026 won’t be the ones with the lowest prices. They’ll be the ones who can respond quickly and accurately to the most opportunities. Estimating capacity is the engine that makes that possible.

At The Cincinnatus Group, we’re “Called to Solve, Where Others Struggle.” Whether you need surge capacity for Q1, specialized support for complex industrial projects, or a strategic partner to help you bid more and win more, we’re ready to help you build 2026 into your strongest year yet.

Ready to discuss your 2026 capacity strategy? Contact The Cincinnatus Group at 878-295-8009 or visit www.tcgduct.com/contact.

Let’s start planning your next success

To learn more about any of the services provided by The Cincinnatus Group, including Contracted Estimating and Take Offs, CAD/BIM/Coordination Drawings, and Contracted Sales Services, please call us at 878-295-8009, or visit our Contact Us page today.