Quality Control Excellence:

How The Cincinnatus Group Achieves Industry-Leading Precision in HVAC Ductwork Estimation

When mistakes are made in HVAC ductwork estimation, even small errors can lead to project delays, budget overruns, and damaged relationships. That’s why quality control isn’t just important—from cost and fabrication to delivery and deadlines, it’s critical to project success.

The Cincinnatus Group knows this firsthand. In 2024, we completed over 2,200 estimates for mechanical and HVAC contractors across the country. But here’s what really matters: we’ve reduced our corrective action reports from seven in 2024 to zero so far in 2025. That’s not luck. That’s the result of a systematic approach to quality control that transforms how ductwork estimation gets done.

“No one in the world does it the way we do it,” explains Drew McCaffrey, owner of The Cincinnatus Group. After 21 years in the business, that’s not just confidence talking—it’s proven results.

The Foundation: EOS and the Process Component

Seven years ago, The Cincinnatus Group embarked on a mission to improve quality control in HVAC estimation to new levels. They adopted the Entrepreneurial Operating System (EOS), a comprehensive business framework that helps companies achieve their vision through focused execution. If you’re not familiar with it, EOS focuses on six key components to drive success: Vision, People, Data, Issues, Process, and Traction. It gives companies practical tools to help leadership teams execute their mission with discipline, and foster a cohesive, accountable environment.

“EOS gives us the ability to laser focus our organization,” Drew explains, “and one component we explored more than the others was process. That journey has taken us to a new level of quality and precision that is unmatched in the industry.”

While many companies rely on individual talent and hope for the best, TCG built a system where excellence is repeatable and scalable. The process component of EOS isn’t about creating rigid rules—it’s about documenting what works, training everyone to that standard, and continuously improving based on real-world results.

This systematic approach means that whether you’re the first estimate of the day or the two-thousandth of the year, you get the same meticulous attention to detail. It’s the difference between a company that depends on exceptional employees and one that creates an environment where everyone can deliver superstar results.

And while The Cincinnatus Group can boast of an exceptional workforce, when everyone follows proven processes, quality becomes predictable, and that predictability is what contractors count on when deadlines loom and budgets are tight.

The SCAR/CAR System: Learning from Every Experience

One of the most powerful tools in TCG’s quality control arsenal is the SCAR/CAR system. TCG’s Senior Operations Manager, Scott Gordon, brought his manufacturing background to the company and introduced SCAR (Supplier Corrective Action Reports) and CAR (Corrective Action Reports) systems that transformed how TCG handles errors.

“We make a mistake once, but not a second time,” Scott emphasizes. “When something goes wrong, we educate the whole team and learn as a group.”

The numbers prove it works. In 2024, TCG had seven corrective action reports—situations where something didn’t meet their exacting standards. By implementing systematic learning from each incident, they’ve achieved zero CARs so far in 2025, despite handling over 1,100 estimates to date.

Here’s how it works: When an issue arises, it’s not swept under the rug or blamed on an individual. Instead, it becomes a learning opportunity. The team documents what happened, why it happened, and most importantly, how to prevent it from happening again. This information spreads across the entire estimating department, turning one person’s experience into everyone’s expertise.

The beauty of the system is its simplicity. Rather than creating a culture of fear around falling down, TCG built a culture of continuous improvement based on learning from errors. Team members feel safe reporting issues because they know it leads to better processes, not blame. This transparency is crucial for maintaining quality at scale.

Standard Operating Procedures: Managing Complexity at Scale

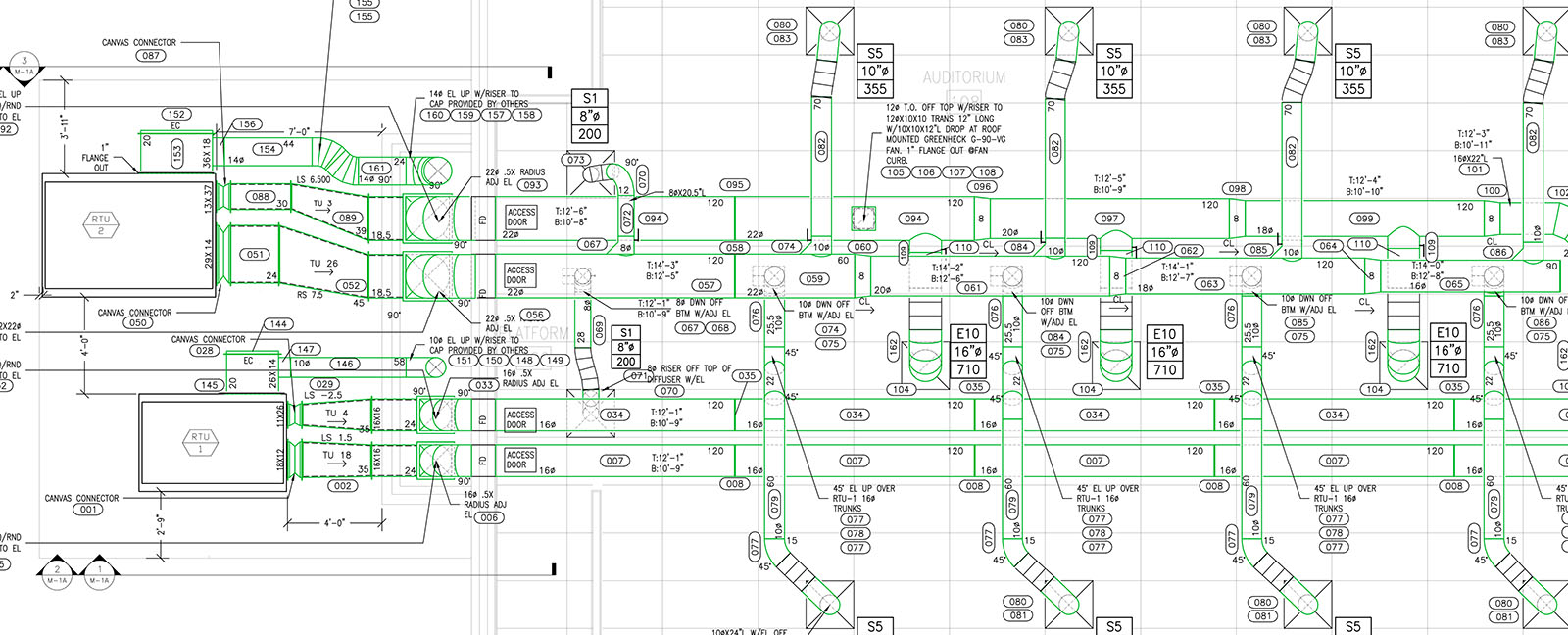

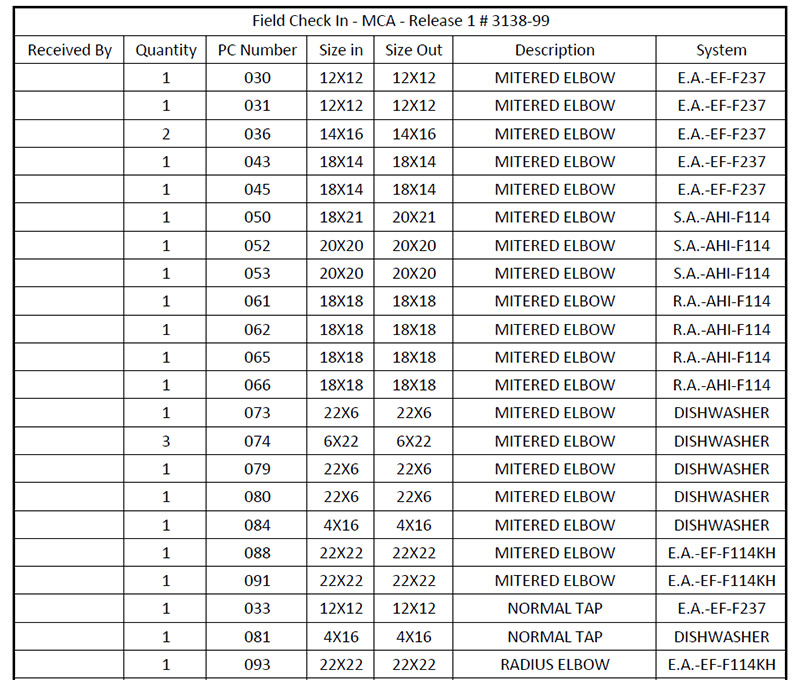

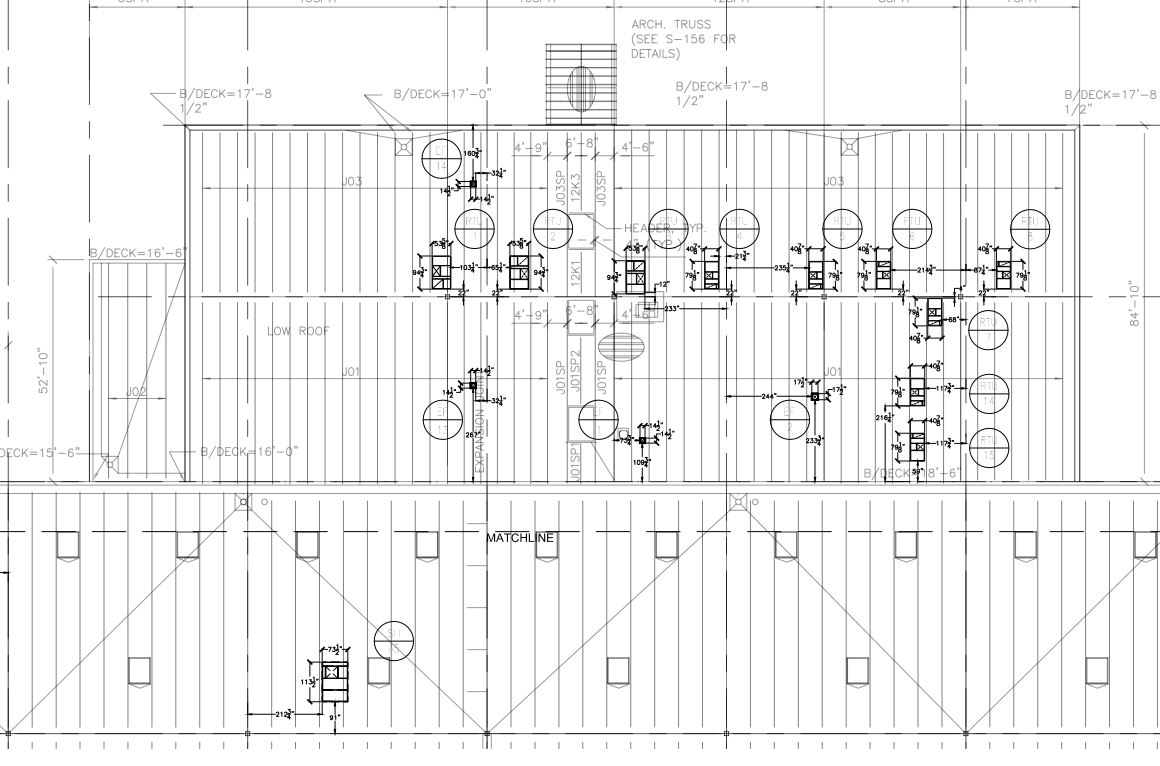

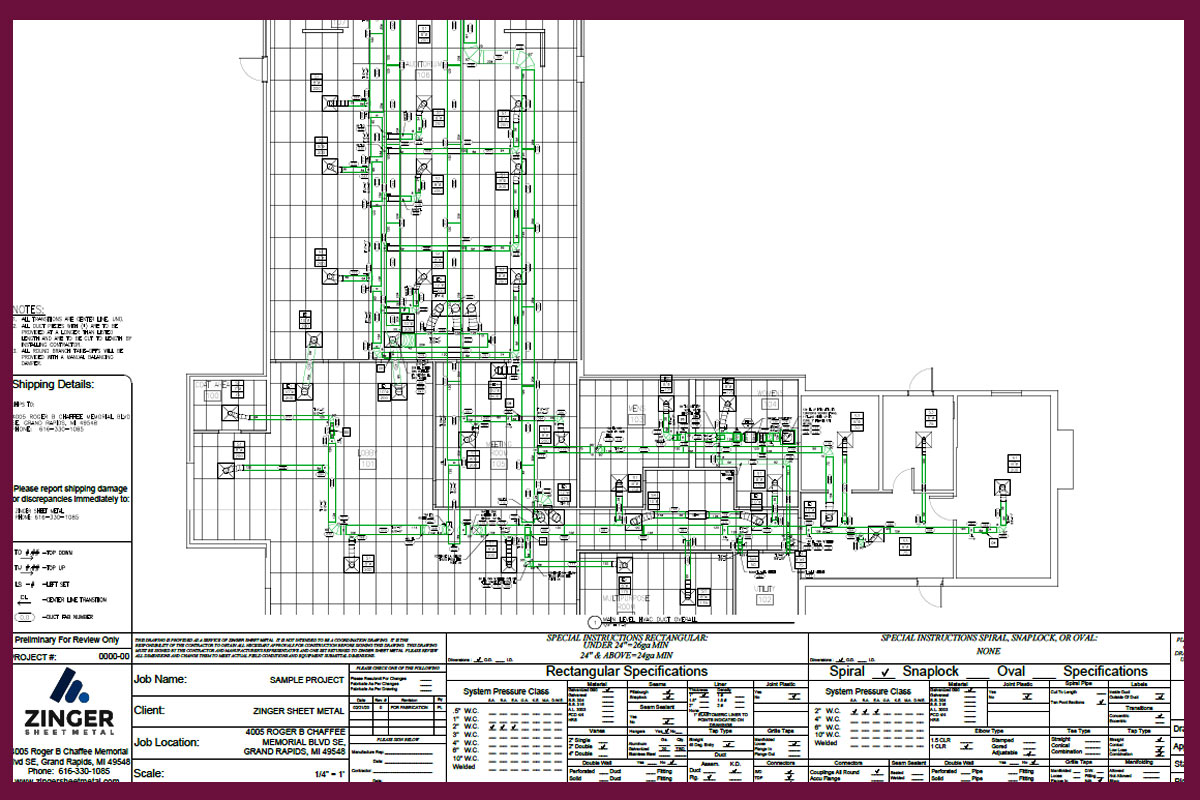

Every contractor has unique needs. Some want detailed breakdowns of rectangular versus round duct. Others need specific gauge requirements highlighted. A few require custom notes about specialized installation methods. Managing this complexity across thousands of estimates could be a recipe for chaos—unless you have rock-solid Standard Operating Procedures (SOPs).

“With all the different clients and their unique needs, our SOPs are what enable us to execute consistently for each client,” Drew explains. “Just this year alone, we’ve handled an incredible variety of specialized requests.”

At The Cincinnatus Group, SOPs are living documents that evolve with client needs and industry changes. They cover everything from how to handle special material requirements to the specific format each client prefers for their estimates.

One fabricator client explains why this matters: “The more data the better. The Cincinnatus Group has shown they can sort through what is needed, so we don’t omit any information.” This client appreciates how TCG’s procedures ensure nothing gets missed, even when requirements are complex.

The procedures also help new team members get up to speed quickly. Instead of spending months learning each client’s preferences through trial and error, they can reference clear guidelines that capture years of accumulated knowledge. This systematization is especially valuable given that TCG uses Quote Express, software that has remained largely static for years. As Drew points out, while the software stays the same, “our team get better.”

Client Testimonials: Proof of Excellence

Numbers tell part of the story, but client feedback reveals the real impact of TCG’s quality control measures. That’s why The Cincinnatus Group gives every customer a satisfaction survey so that their feedback can make a difference. Of course, in addition to the hard work of using feedback for improvement, it’s also important to acknowledge the wins.

Across the board, satisfaction ratings consistently hit the highest marks.

“I’d give your team a 5 out 5!” says a project manager from a major mechanical contracting firm. This wasn’t just politeness—it came after detailed discussion about TCG’s services over the past year.

A specialty duct fabricator who’s been with TCG for several years notes: “Yes, absolutely,” when asked if TCG’s team demonstrates strong work ethic, accountability, and pursuit of excellence. “It shines through with all of your people.”

One industrial contractor puts it simply: “5 for sure!” when rating satisfaction levels. They went on to explain that TCG provides far superior service compared to three other companies they evaluated. “We definitely see the value, and TCG delivers a far superior product.”

On the return on investment front, one client reported “a very high ROI” and specifically mentioned winning back customers “to the tune of $100k – maybe $300k” in increased business. Quality control isn’t just about avoiding mistakes—it’s about enabling client success.

Perhaps most telling is when one of TCG’s clients undergoes an owner ship change and the quality of service speaks for itself and is maintained by the new regime. For the staff at The Cincinnatus Group, that’s the ultimate vote of confidence.

Even when issues arise, clients appreciate TCG’s response. One fabricator mentioned past challenges but noted: “TCG jumped in immediately to resolve the issue, helped with conversations with the client, handled things the right way and gave a discount on hours, so yes all was resolved.”

The Human Capital Solution

Why do contractors turn to TCG for help with estimating? Owner Drew McCaffrey sees three main scenarios playing out repeatedly across the industry.

“People come to us because of lack of human capital,” he explains. “They have someone doing it internally, that person leaves or retires, or they get so busy their current people can’t keep up. They are desperate to get it done. Customers are screaming for numbers.”

This desperation creates a trust challenge. How can contractors be confident that an outside company will maintain the quality standards their reputation depends on? As we’ve seen in this article, the answer lies in TCG’s systematic approach to quality control.

“Historically, our success has been based on the trust level customers have in us to get the job done and the relationships I’ve built with our clients over the years” Drew says. “But it’s not just about me as the founder and owner anymore—it’s about the system we’ve built.”

This systematic approach is especially important as TCG expands its reach. “We first introduced our services in the non-union world, and now our offerings have branched out into the SMACNA world,” Drew notes. The company recently achieved SMACNA Bronze Associate Member status, opening doors to serve union contractors who demand the highest standards.

The human capital crisis in the construction industry isn’t going away. If anything, it’s getting worse as experienced estimators retire and fewer young people enter the trades. TCG’s quality control systems offer a solution that doesn’t depend on finding those exceptional, unicorn employees—instead, it creates an environment where good people can deliver excellent results consistently.

Conclusion: Called to Solve Where Others Struggle

The Cincinnatus Group’s journey isn’t about perfection—it’s about building systems that catch and correct issues before they impact clients. It’s about turning individual knowledge into team wisdom. It’s about creating processes that deliver consistent excellence across thousands of estimates.

For contractors struggling with estimation capacity, accuracy, or consistency, TCG’s approach offers more than just a service—it provides peace of mind. When you’re juggling multiple projects, managing field crews, and trying to win new business, the last thing you need is to worry about whether your ductwork estimates are accurate.

The combination of EOS principles, manufacturing-grade quality control systems, detailed SOPs, and a culture of continuous improvement creates something unique in the industry. As one satisfied client put it: “TCG provides the ability for us to branch out into new areas, whereas companies like ours just can’t do it alone.”

Looking ahead, TCG continues to invest in improvement. New software implementations are planned for next year, adding even more capability to their already strong foundation.

Whether you’re a mechanical contractor dealing with a retired estimator, an HVAC company overwhelmed by growth, or a fabricator seeking reliable estimation support, The Cincinnatus Group’s quality control systems deliver one thing above all: results you can trust.

In an industry where reputation is everything and mistakes are costly, that’s not just valuable—it’s essential. The Cincinnatus Group is “Called to Solve, Where Others Struggle,” and their zero-CAR achievement proves they’re living up to that promise.

For more information about The Cincinnatus Group’s estimating services and quality control processes, contact them at 878-295-8009 or visit www.tcgduct.com.

Let’s start planning your next success.

To learn more about any of the services provided by The Cincinnatus Group, including Contracted Estimating and Take Offs, CAD/BIM/Coordination Drawings, and Project Management Assistance, please call us at 878-295-8009, or visit our Contact Us page today.